In today’s rapidly evolving industrial landscape, the demand for efficient and reliable filtration systems is on the rise. One key component in these systems is the filter cartridge, which plays a crucial role in removing impurities from various liquids and gases. To meet this growing demand, manufacturers are constantly innovating their production processes, leading to the development of advanced technologies such as the filter cartridge winding machine.

The Importance of Filter Cartridge Winding Machine

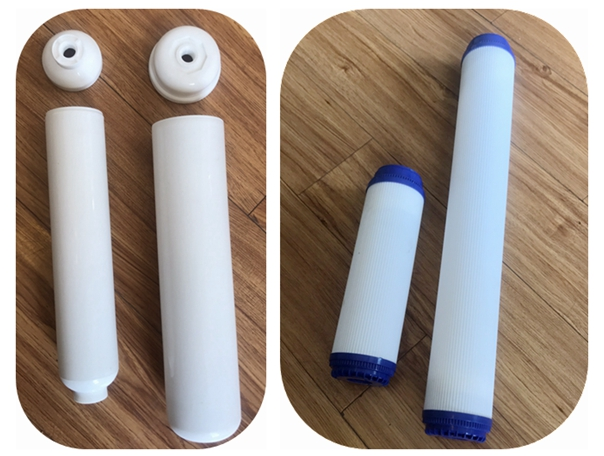

The filter cartridge winding machine revolutionizes the manufacturing process by automating and streamlining the production of high-quality filter cartridges. This cutting-edge equipment enables precise control over critical parameters like diameter, length, and pleat count during winding operations. By ensuring consistent product quality and reducing human error, it enhances overall efficiency while meeting stringent industry standards.

Hongteng: A Leading Innovator

One prominent player in this field is Hongteng Machinery Co., Ltd., a renowned manufacturer specializing in filtration equipment. With years of experience and expertise, Hongteng has developed state-of-the-art filter cartridge winding machines that cater to diverse market needs.

Hongteng’s machines offer customizable features that allow manufacturers to adapt their production processes according to specific market requirements. Whether it’s different diameters or varying pleat counts for specialized applications such as water treatment or pharmaceuticals, Hongteng ensures flexibility without compromising on precision.

The Carbon Filter Cartridge Making Machine Advantage

A notable innovation by Hongteng is their carbon filter cartridge making machine. This specialized equipment addresses the increasing demand for effective air purification solutions across industries like automotive manufacturing and HVAC systems.

The carbon filter cartridge making machine incorporates advanced technology to efficiently embed activated carbon particles into each layer of the filter cartridge. This ensures maximum adsorption capacity and superior air purification performance, making it an ideal choice for applications where odor and volatile organic compounds (VOCs) removal is critical.

Conclusion

The filter cartridge winding machine has emerged as a game-changer in the filtration industry, enabling manufacturers to produce high-quality cartridges with precision and efficiency. Hongteng’s commitment to innovation and customization further enhances its position as a leading provider of these advanced machines. With the introduction of specialized equipment like the carbon filter cartridge making machine, Hongteng continues to meet evolving market demands while ensuring cleaner environments across various sectors.