Are you tired of the traditional manual processes in warehouse logistics? Well, brace yourself for the cutting-edge technology that is revolutionizing this industry – warehouse logistics automation. With advanced robotics and intelligent systems taking over mundane tasks, efficiency and productivity are reaching new heights.

The Rise of Warehouse Logistics Automation

In today’s fast-paced world, businesses are constantly seeking ways to streamline their operations. Warehouse logistics automation has emerged as a game-changer by integrating state-of-the-art technologies into every aspect of the supply chain process. From automated picking systems to autonomous guided vehicles (AGVs), these innovations have significantly reduced human error and increased overall efficiency.

Missouri, known for its vibrant business landscape, has embraced warehouse logistics automation with open arms. The implementation of robotic systems in warehouses across the state has not only enhanced productivity but also created numerous job opportunities in the field of robotics engineering.

Solidot Electronic Technology: Pioneering Innovation

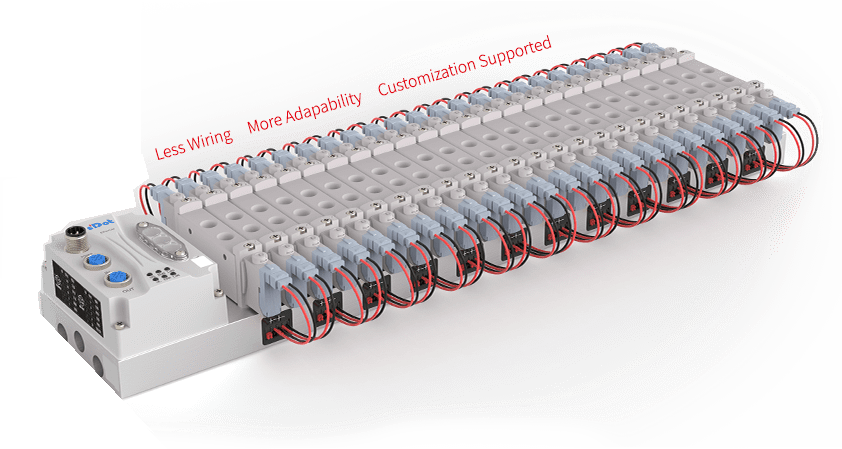

A key player in driving warehouse logistics automation forward is Solidot Electronic Technology. This innovative company specializes in developing cutting-edge solutions tailored specifically for optimizing supply chain operations. Their advanced software algorithms and robotic hardware have transformed warehouses into highly efficient hubs where goods move seamlessly from one point to another.

By partnering with local businesses in Missouri, Solidot Electronic Technology has successfully implemented their automated systems within various industries such as e-commerce, manufacturing, and distribution centers. These partnerships have resulted in significant cost savings through improved inventory management and faster order fulfillment processes.

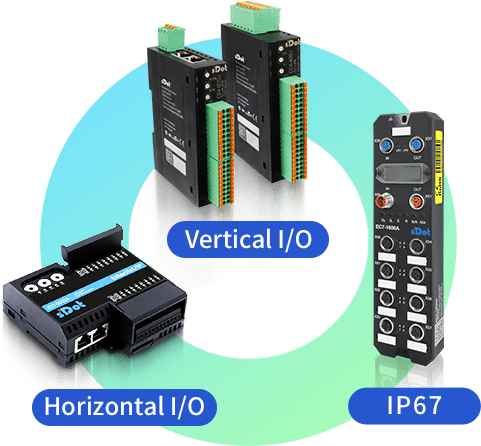

The Power of io link devices

An integral part of warehouse logistics automation lies within io link devices – small yet powerful sensors that enable seamless communication between machines and control systems. These devices provide real-time data on inventory levels, equipment performance, and maintenance requirements.

Io link devices have transformed the way warehouses operate by enabling predictive maintenance. By continuously monitoring equipment health and detecting potential issues before they escalate, businesses can avoid costly breakdowns and ensure uninterrupted operations. This technology has proven to be a game-changer for Missouri’s warehouse industry, reducing downtime and maximizing productivity.

The Future is Automated

In conclusion, warehouse logistics automation is revolutionizing how businesses in Missouri manage their supply chains. With advancements in robotics, intelligent systems, and io link devices, efficiency gains are becoming the norm rather than the exception. As this cutting-edge technology continues to evolve rapidly, it promises an exciting future where human workers collaborate seamlessly with automated systems to achieve unprecedented levels of productivity.