In today’s fast-paced business world, efficient logistics management is crucial for companies to stay competitive. With the advent of advanced technologies, robot logistics has emerged as a game-changer in streamlining operations and optimizing supply chains.

The Role of Robot Logistics

Robot logistics refers to the use of autonomous robots in various stages of the supply chain process, including warehousing, order fulfillment, and transportation. These intelligent machines are equipped with sensors and artificial intelligence algorithms that enable them to perform tasks traditionally carried out by humans.

By leveraging robot logistics, businesses can significantly enhance their operational efficiency. Robots can work tirelessly around the clock without fatigue or breaks, ensuring continuous productivity. They also minimize errors and improve accuracy through precise data analysis and real-time monitoring capabilities.

The Importance of Robotics Repair

To ensure uninterrupted operations and maximize cost savings in robot logistics systems, robotics repair plays a vital role. As with any technology-driven solution, occasional malfunctions or breakdowns may occur due to wear and tear or technical glitches.

Rather than relying solely on external repair services which might cause delays in production schedules or incur high costs, many companies have established dedicated robotics repair teams within their facilities. These teams consist of skilled technicians who possess expertise in diagnosing issues promptly and implementing effective repairs efficiently.

Youibot: A Leading Provider

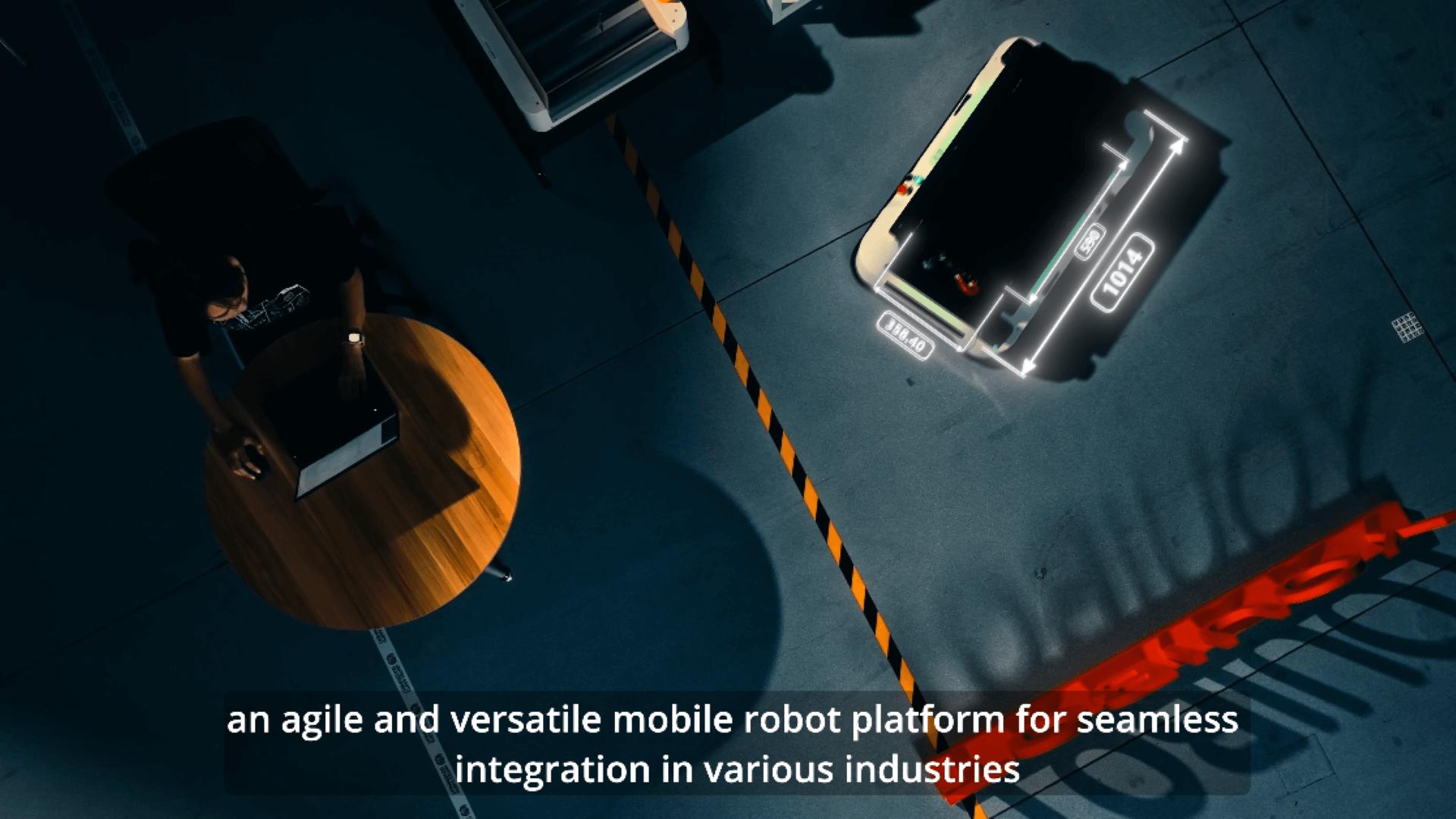

One prominent player revolutionizing robot logistics is Youibot – a leading provider of intelligent mobile robots for industrial applications. Their cutting-edge robotic solutions offer seamless integration into existing warehouse environments while delivering exceptional performance metrics.

Youibot’s robots are designed with versatility in mind – they can navigate complex terrains effortlessly using advanced mapping algorithms combined with obstacle detection capabilities. Moreover, these robots can handle various tasks, such as picking and placing items, inventory management, and even collaborative operations with human workers.

The Cost-Benefit Analysis

When considering the implementation of robot logistics systems, conducting a cost-benefit analysis is crucial. While the initial investment in robotics technology may seem significant, it is essential to evaluate the long-term benefits that outweigh these costs.

Robot logistics offers substantial advantages such as increased productivity, reduced labor costs, improved accuracy and efficiency, enhanced safety measures for employees working alongside robots, and faster order fulfillment. These benefits translate into higher customer satisfaction levels and ultimately contribute to business growth.

In conclusion,

Robot logistics has revolutionized supply chain management by introducing autonomous robots capable of performing various tasks efficiently. With companies like Youibot leading the way in providing intelligent mobile robotic solutions tailored for industrial applications, businesses can optimize their operations while enjoying significant cost savings. By embracing this technological advancement and conducting thorough cost-benefit analyses beforehand, organizations can stay ahead of the competition in today’s dynamic market landscape.