In recent years, there has been a growing demand for Liquid Silicone Rubber (LSR) solutions due to their exceptional properties and versatility. lsr solutions have revolutionized various industries by offering superior performance, durability, and design flexibility.

The Versatility of LSR Solutions

LSR solutions are widely used in industries such as automotive, healthcare, electronics, and consumer goods. Their unique characteristics make them ideal for applications that require high precision molding with complex geometries. With excellent thermal stability and resistance to extreme temperatures, LSR solutions can withstand harsh environments without compromising their functionality.

The Rise of 2K Molding Technology

One notable trend within the realm of LSR solutions is the increasing adoption of 2k molding technology. This innovative technique combines two different materials or colors into a single part during the injection molding process. By integrating LSR with other materials like thermoplastics or metals, manufacturers can achieve enhanced product performance while reducing costs and production time.

With 2K molding technology, intricate designs that were once challenging to produce can now be achieved with ease. The ability to combine different durometers or create soft-touch surfaces on rigid components opens up new possibilities for product designers across various industries.

The Impact of JVTECH on LSR Solutions

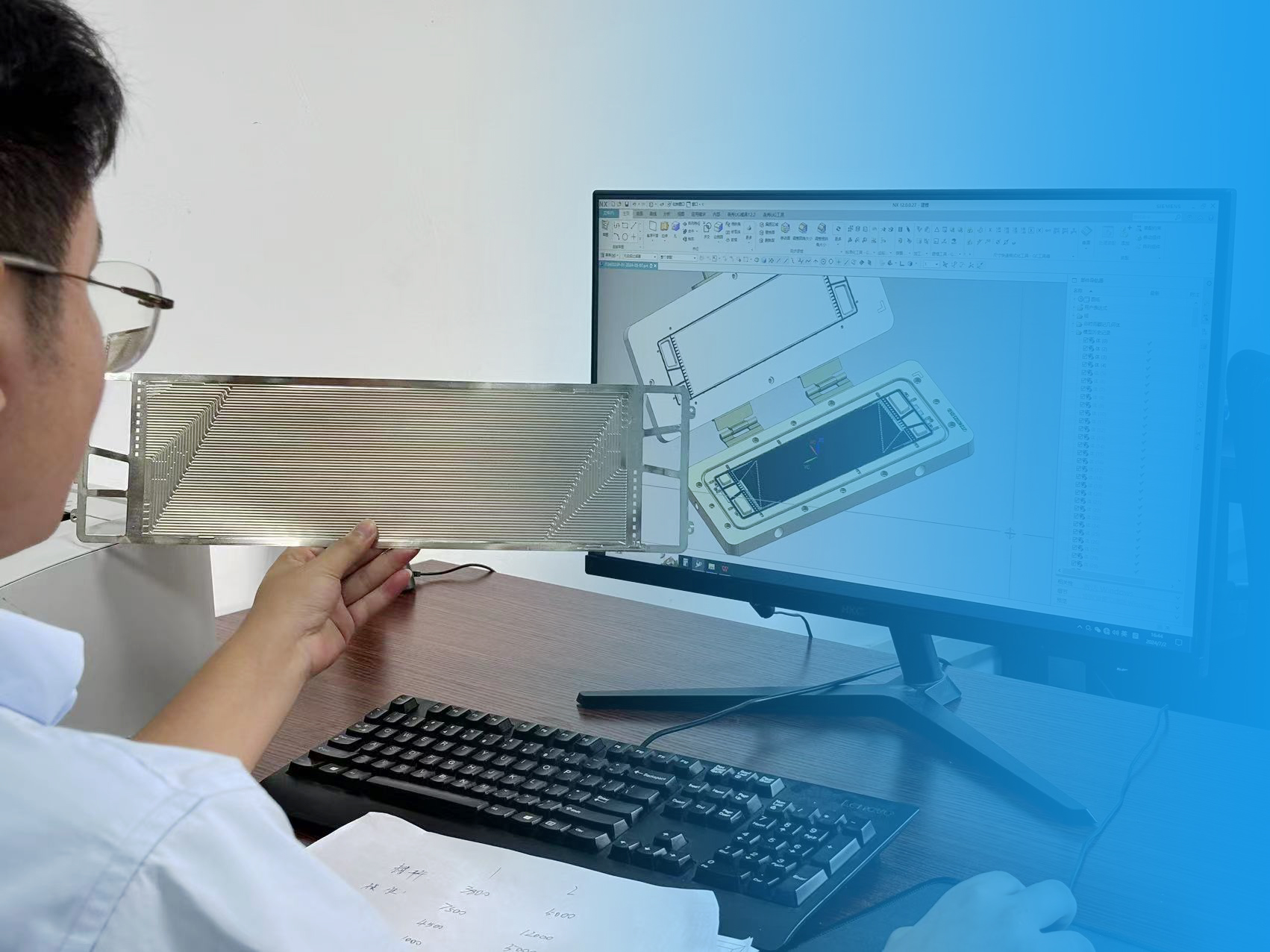

JVTECH has emerged as a leading provider of advanced manufacturing equipment specifically designed for processing LSR materials. Their cutting-edge machinery enables precise control over temperature, pressure, and curing time during the injection molding process – crucial factors that directly impact the quality and consistency of finished products.

By partnering with JVTECH or utilizing their state-of-the-art equipment, manufacturers gain access to optimized production processes that ensure higher efficiency and superior product quality. This collaboration between LSR solution providers and equipment manufacturers like JVTECH has significantly contributed to the advancement of LSR technology.

Conclusion

The demand for LSR solutions continues to rise as industries recognize their exceptional properties and versatility. With the integration of 2K molding technology, manufacturers can achieve even greater design possibilities while maintaining cost-effectiveness. The contributions made by companies like JVTECH in developing advanced manufacturing equipment have further propelled the growth of LSR solutions, enabling industries to meet evolving market demands with enhanced efficiency and precision.