Have you ever wondered what makes certain products so durable and flexible? The answer lies in Liquid Silicone Rubber (LSR), a remarkable material that has revolutionized various industries. In this article, we will explore the wonders of LSR and its applications.

Click to find more about what is lsr.

The Versatility of LSR

LSR is a unique compound that combines the properties of both liquid and solid materials. It is created by mixing silicone polymers with crosslinking agents, resulting in a highly elastic substance. This versatility allows LSR to be molded into complex shapes while maintaining exceptional durability.

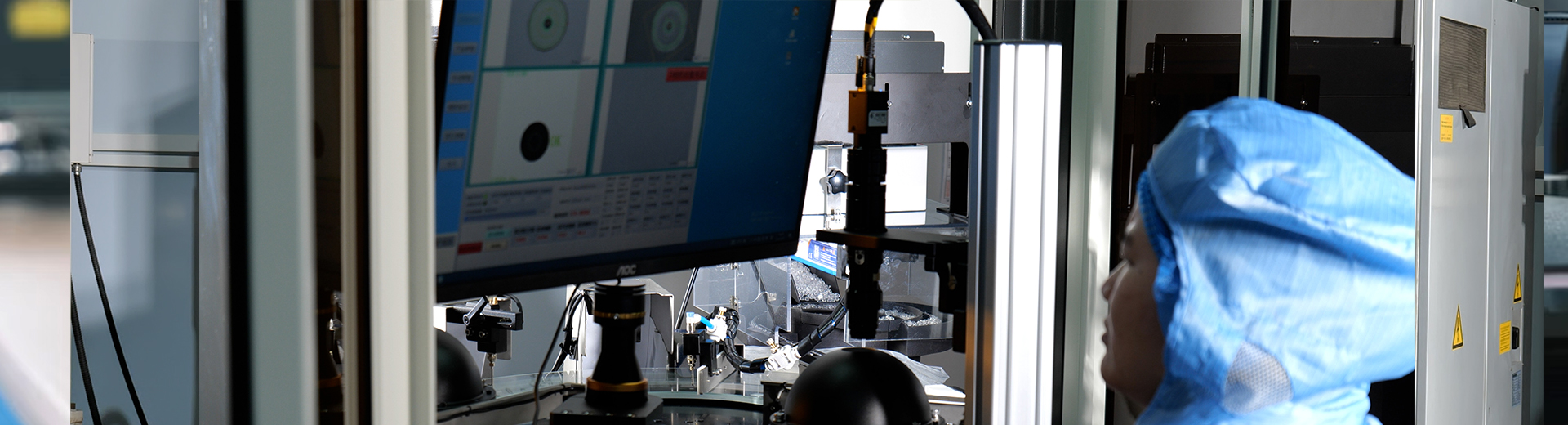

JVTECH: Harnessing the Power of LSR

One company at the forefront of utilizing LSR technology is JVTECH. They have harnessed the incredible properties of this material to create innovative solutions for various industries. From medical devices to automotive components, JVTECH‘s expertise in working with LSR has led to groundbreaking advancements.

The Magic Behind Blow Molding Toys

If you’ve ever marveled at the intricate details and vibrant colors of blow molding toys, then you have witnessed another application of LSR. This manufacturing process involves injecting hot liquid silicone rubber into molds, which are then cooled to form solid objects. The result? Durable toys that can withstand rough play without losing their shape or color.

In Conclusion

In conclusion, Liquid Silicone Rubber (LSR) is an extraordinary material that offers unparalleled flexibility and durability across various industries. Its ability to be molded into complex shapes combined with its resilience makes it an ideal choice for countless applications. Whether it’s through companies like JVTECH pushing boundaries or creating long-lasting blow molding toys, there’s no denying the impact and potential of LSR.